Date: Jul 22, 2024 Views:

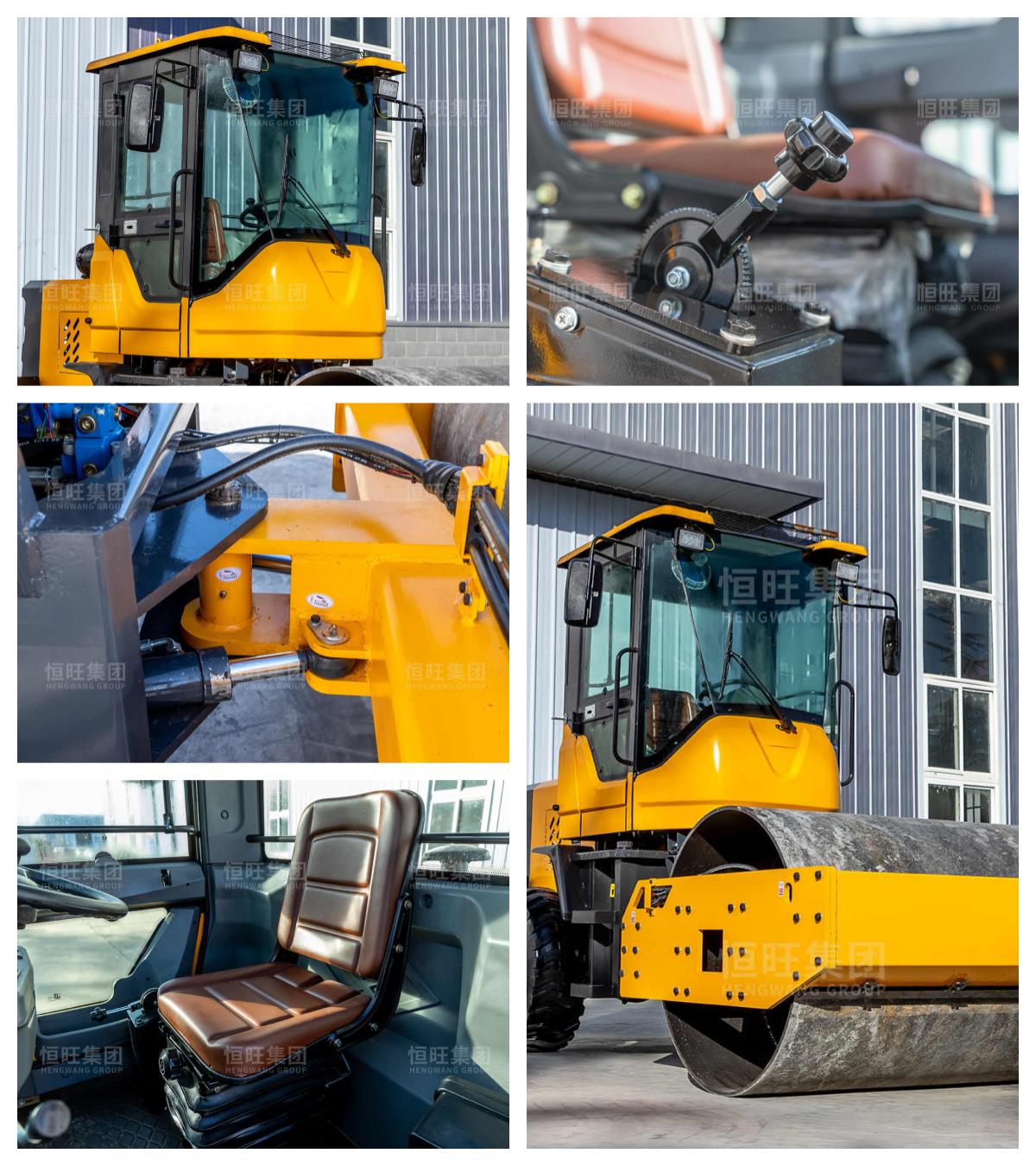

Let's get you acquainted today - Road Rollers

A road roller is a piece of heavy-duty construction equipment that is primarily used to compact a variety of building materials and soils to ensure that they have adequate load-bearing capacity and

stability. The following are some common materials and uses that can be compacted by rollers:

1. Soil: Compacting soil is one of the basic uses of road rollers, especially in construction sites, road building and land development.

2. Gravel: In road base layers, rollers are used to compact gravel to provide a stable and solid base.

3. asphalt: after laying asphalt, rollers are used to compact the asphalt layer to ensure that it bonds to the layer below and creates a smooth surface.

4. concrete: in some cases, rollers can also be used to compact concrete, especially in the construction of large concrete slabs.

5. gravel and sand: in the construction of drainage or fill layers, rollers can be used to compact gravel and sand.

6. Landfills: In environmental engineering, rollers are used to compact waste in landfills, reducing the volume and preventing the waste from moving.

7. Railroad tracks: In railroad construction, rollers are used to compact the track bed and ensure the stability of the tracks.

The following steps are typically followed in the use of rollers:

1. Preparation: Before starting compaction, the construction area needs to be cleared and debris and obstacles removed.

2. Laying Material: The material to be compacted (e.g. soil, gravel, etc.) is laid down to a specified thickness.

3. Initial Compaction: Initial compaction is carried out using a roller, usually starting at the edges and gradually moving towards the center.

4. Overlapping Compaction: With each compaction, the roller wheels or drums should slightly overlap the path of the previous compaction to ensure that the entire area is compacted.

5. Multiple Compaction: Depending on the type of material and desired density, multiple compaction passes may be required.

6. Checking: After compaction is complete, use a density testing tool (e.g., a nuclear density meter) to check that the compaction meets the design requirements.

7. Adjustment: If compaction is inadequate, further compaction or addition of more material may be required.

There are various types of rollers, including single drum vibratory rollers, tire rollers and static rollers, etc. Different types of rollers are suitable for different compaction tasks and materials. Proper

use of road rollers can improve construction efficiency and ensure project quality.